Home > Products > Fibre Optical Cables > Optic Fibre Cable (Double Sheath)

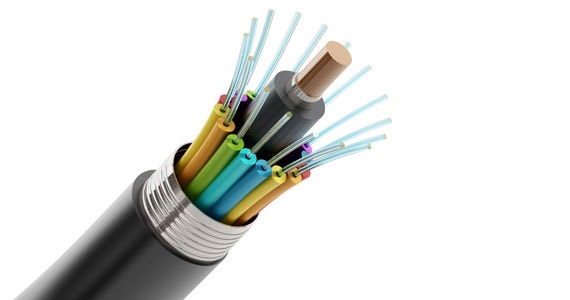

- 1. Fibre Reinforced Plastic as dielectric central strength member.

- 2. Six Poly Butylene Terephthalate (PBT) loose tubes stranded around the central strength member to form the cable core.

- 3. Optic Fibre are housed in loose tube.

- 4. Thixotropic jelly injected in loose tube with Fibre.

- 5. Polyester tape is wrapped around the cable core.

- 6. Interstices within the cable core flooded with jelly.

- 7. High-density polyethylene sheath as a inner sheath.

- 8. Inner sheath is covered with a corrugated SS tape/ FCCS tape.

- 9. Anti-termite HDPE jacket extruded over corrugated SS tape as outer sheath.

|

Applications

|

|

| Technical Specifications From 6F to 48F Cable | |||||||||||||||||||||||||||||||||||||

| Description | Typical Values | ||||||||||||||||||||||||||||||||||||

| Single Mode Optic Fibre | Complying to ITU G. 652 | ||||||||||||||||||||||||||||||||||||

| Fibre Colour Code | Blue, Orange, Green, Brown, Slate / Grey, White, Red, Black, Yellow, Violet, Rose / Pink, Natural / Aqua | ||||||||||||||||||||||||||||||||||||

| Buffer Loose Tube Colours(Optional) | Blue, Orange, Green, Brown,Slate / Grey, White, Red, Black, Yellow, Violet, Rose / Pink, Natural / Aqua | ||||||||||||||||||||||||||||||||||||

| Optical Performance | Attenuation @ 1310nm, ≤ 0.38dB / km, Attenuation @ 1550nm, ≤ 0.25dB / km | ||||||||||||||||||||||||||||||||||||

| Mechanical Performance | Tensile Strength | Min Bend Radius | Impact | Torsion | |||||||||||||||||||||||||||||||||

| 1W | 1.3W | 2.0W | 2.5W | 20D | 50N | 400N | |||||||||||||||||||||||||||||||

| Enviornmental Performance | Temperature | Operating | Installation | Storage / Shipping | |||||||||||||||||||||||||||||||||

| Specification | -20°C to + 70° C | -20°C to + 70° C | -30°C to + 70° C | ||||||||||||||||||||||||||||||||||

| Physical |

|

||||||||||||||||||||||||||||||||||||

| Testing & Inspection |

|

||||||||||||||||||||||||||||||||||||