Fire Survival / Resistant Cables

In the event of a fire, the biggest obstacles to safe evacuation are smoke, heat, and toxic fumes. To mitigate these hazards, it is crucial to use fire-resistant and non-halogenated cables. Relemac has added a special range of Fire Survival & Fire Resistant cables to its product portfolio. Our Fire Survival Cables are designed to remain operational for a minimum duration during a fire, even when exposed to water spray and mechanical shock. Our Fire Resistant Cables are rigorously tested in NABL accredited labs like ERDA Baroda to ensure the highest quality products. These cables are vital for ensuring the safety of people and property, particularly in areas prone to fire hazards. As one of the leading Fire Survival Cables Suppliers, Relemac provides a comprehensive range of high-quality fire-resistant cables that meet various industry standards and regulatory requirements.

Fire Survival & Fire Resistant cables

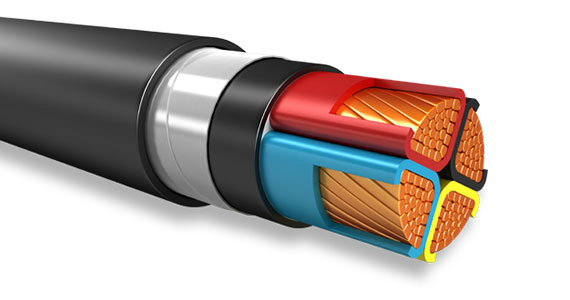

Conductor :

Electrolytic Grade Copper Bare / Tinned, Solid / Stranded / Annealed Flexible Conductors conforming to IS:8130:1984 or other international standard.

Fire Barrier :

Conductor is insulated with Mica Glass Tape that is Fire Resisting Barrier.Mica Tape survives temperature up to 1000C. It is Low smoke and non-toxic, chemically neutral and Zero Halogen gases free.

Core Identification

Relemac Fire Resistant cable may be single-core or multi-core constructions.

Primary Insulation :

The Insulated material may be Heat Resistant PVC / XLPE / EPR / EVA / Silicon Rubber or any other dielectric material as per customers specification.

Screening :

Individual & Overall Shielding may be of Annealed Tinned Copper Braiding/Poly Aluminum [Thin Layer of Aluminum Foil bonded to Polyester Film] Tape with Annealed Tinned Copper Drain Wire. Braiding ATC Shield has high tensile Strength and provides better coverage in flexing application. It's also done by copper Tape or nickel copper as per specifications.

Inner Sheath :

The Inner Sheath is applied over laid up of cores by extrusion / wrapping of thermoplastic material. The Insulation, Inner Sheath can be Normal Pvc /FR PVC / FRLS PVC / ZHFR / LSF Compound depending upon their application or specfication.

Armour:

Armour is applied over inner Sheath. It may consist of galvanized Round Steel wires or galvanized Flat Steel Strips conforming to IS:3975. Steel wire armoured cables are suitable for direct burial. One or more copper wires can be incorporated in the armour to increase the conductivity of the Armour where it is being used as an earth return. Armour can also by steel tape / double helical steel tape or aluminum wire if client's requirement. Round Wire armoring is provided , where the calculated diameter under Armour is 13.0 m.m. Above this, armoring is either round wire / steel strip as per client's requirement.

Outer Sheath :

A final covering of PVC Compound is applied over Armouring in case of Armoured Cable or over Inner Sheath in case of Unarmoured Cable. The Color of Sheath is Black,Grey or as per customer's choice.The Outer Sheath material may be Flame Retardant LSZH /FR PVC / FRLS PVC as per requirement of the specification.

Standard Specifications :

- Fire resistant - IEC 60331; BS 6387; BS 8491; BS 8434/2

- BS 6387 - CAT A,B,C,W,Z

- BS 7846 - CAT F1, F2, F3

- Flame retardant - IEC 60332- 1 & 3

- Smoke emission - ASTM D 2843

- Acid gas emission - IEC 60754

- Oxygen index - ASTM D 2863

- & other customized & International Standard

Characteristics :

- ► Will withstand Flame temperature of 750 degree centigrade up to 3 hours without electrical breakdown at rated voltage.

- ► During fire condition small quantity of toxic gases mainly, CO, CO2 are inevitably emitted. Fire Survival Cables are designed to limit these toxic gases within safety level.

- ► Corrosive Gases react with moisture to produce active acids which corrode metals causing extensive long term damage. Often these gases spread throughout the building through the ventilation system or within the entire installation. This is particularly damaging to electronic equipments and even to the exposed steel structures or even the concrete enclosed steel structures.

- ► Does not propagate flame.

Typical Application :

Relemac Fire Resistant cables also known as CIRCUIT INTEGRITY CABLES have been developed to maintain circuit integrity in a fire and to ensure the maximum safe evacuation of personnel with no detrimental effects like toxic gases or smoke.These fire retardant cables Specially designed for to maintain Long-term circuit integrity during and after a fire like public address and emergency voice communication systems , fire extinguishing systems, sprinklers pumps, control panels, exit lights in high-rise building control and instrumentation services in industrial, commercial and residential complexes, hospitals, airports, thermal power plants, metro rail projects, rail terminals, malls and crowdy areas etc. data and voice transmission,CCTV, security, smoke detection and evacuation monitoring applications ,interconnection of distribution boxes and end devices, where continued functionality is required during a fire situation ,in High-temperature installation conditions.